Dec 03, 2025

The Future of Grinding: How Robotics is Revolutionizing the Foundry Industry

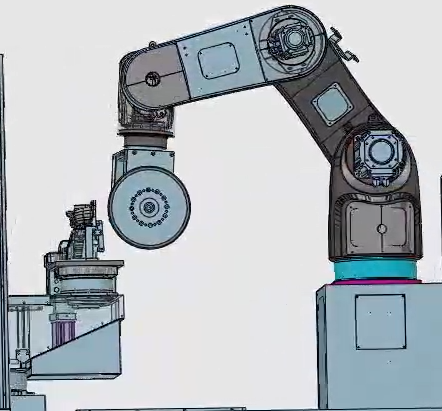

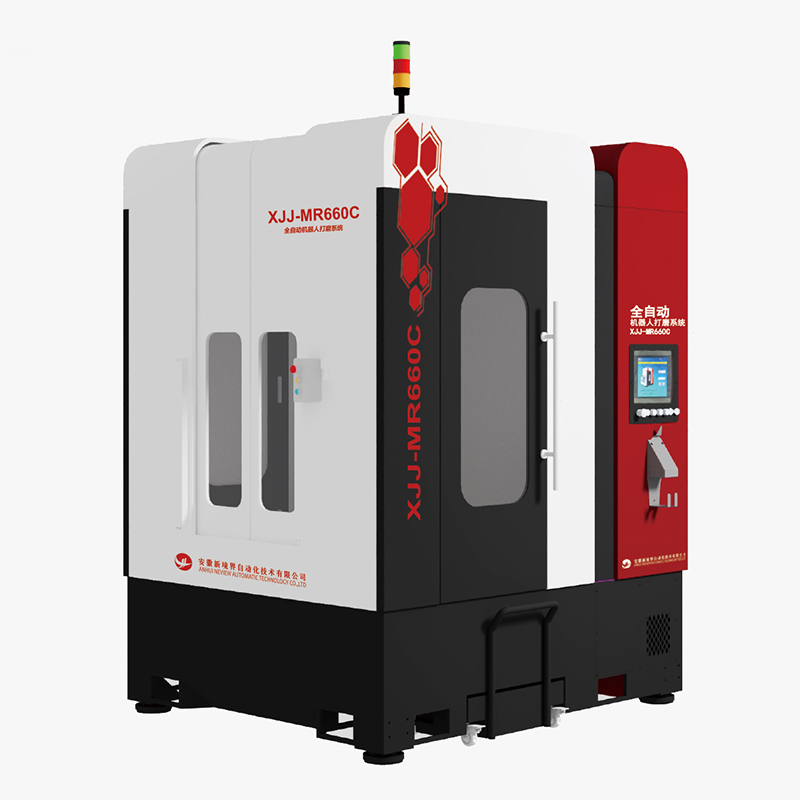

In the foundry industry, manual grinding is essential for producing high-quality castings, but it’s also fraught with challenges. From the difficulty of finding skilled labor to the inconsistent results produced by human workers, the process is often less efficient than it should be. Enter robotics—specifically, the grinding robots from NEVIEW, which are designed to solve these long-standing problems.

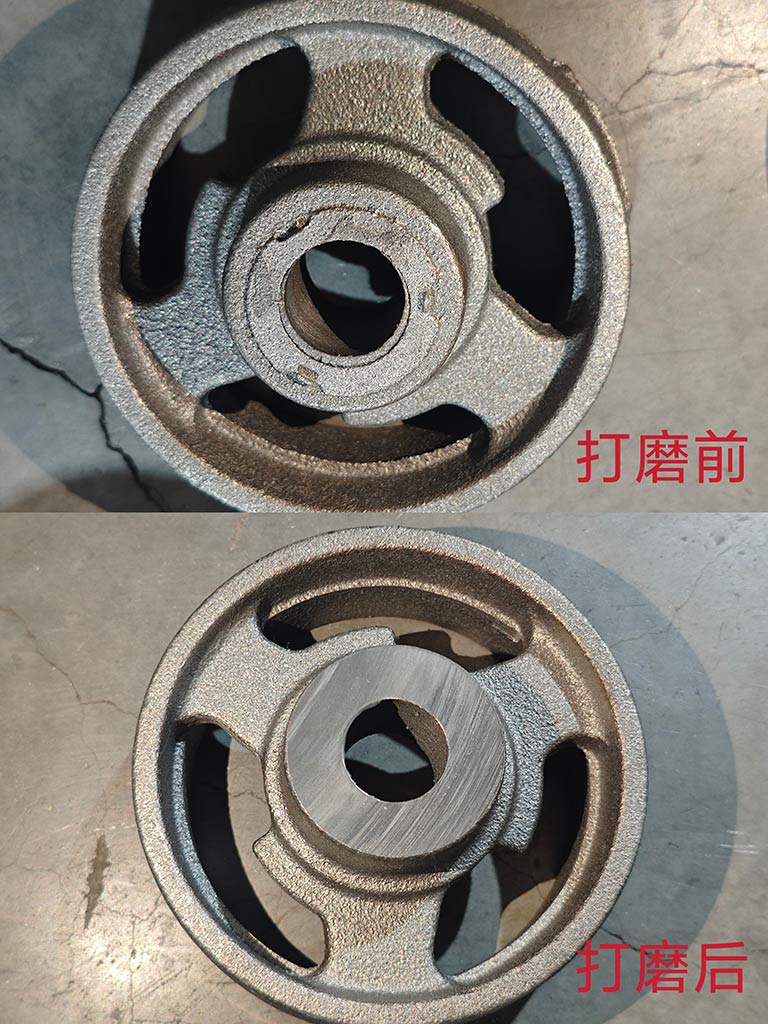

One of the primary benefits of using robots in grinding is the ability to maintain consistent results. Human workers, even the most experienced, can only deliver a limited level of consistency. Robots, however, can perform repetitive tasks with perfect precision, ensuring that each casting meets the exact specifications needed.

Additionally, the rise of robotics in foundries helps address labor shortages and high costs. Skilled workers are becoming increasingly difficult to find and retain, and the cost of human labor continues to climb. With robots, foundries can reduce their reliance on human workers, improving both their productivity and profitability.

At NEVIEW, our grinding robots are designed not just to meet industry standards, but to exceed them. With advanced features such as adaptive grinding pressure, high flexibility, and easy integration into existing production lines, we help foundries achieve better results with fewer resources.

Conclusion With the integration of robotics, the future of grinding in the foundry industry looks brighter than ever before. By reducing reliance on manual labor, improving consistency, and lowering costs, NEVIEW’s grinding robots are setting the stage for a new era in manufacturing.

Read More