Dec 25, 2025

Robotic Grinding Terminology Explained: A Beginner’s Guide to Casting Industry Terms

The world of robotic grinding is full of technical jargon, which can be overwhelming for newcomers to the field. Understanding these key terms is essential for making informed decisions when selecting and utilizing robotic systems in your foundry. This guide breaks down the most common terminology related to robotic grinding and explains how they impact performance.

Key Terms Explained:

8-Axis 7-Linkage: This refers to the robot's ability to move in 8 axes, with 7 of them being interlinked, allowing the robot to perform complex movements in 3D space. This system provides extreme flexibility and precision, enabling the robot to grind parts with intricate shapes or hard-to-reach areas.

Rigidity and Flexibility: Rigidity refers to the robot's structural stability when applying grinding force, which is necessary for precision tasks. Flexibility, on the other hand, refers to the robot’s ability to adapt to various part geometries. A balance between rigidity and flexibility is crucial for effective grinding performance.

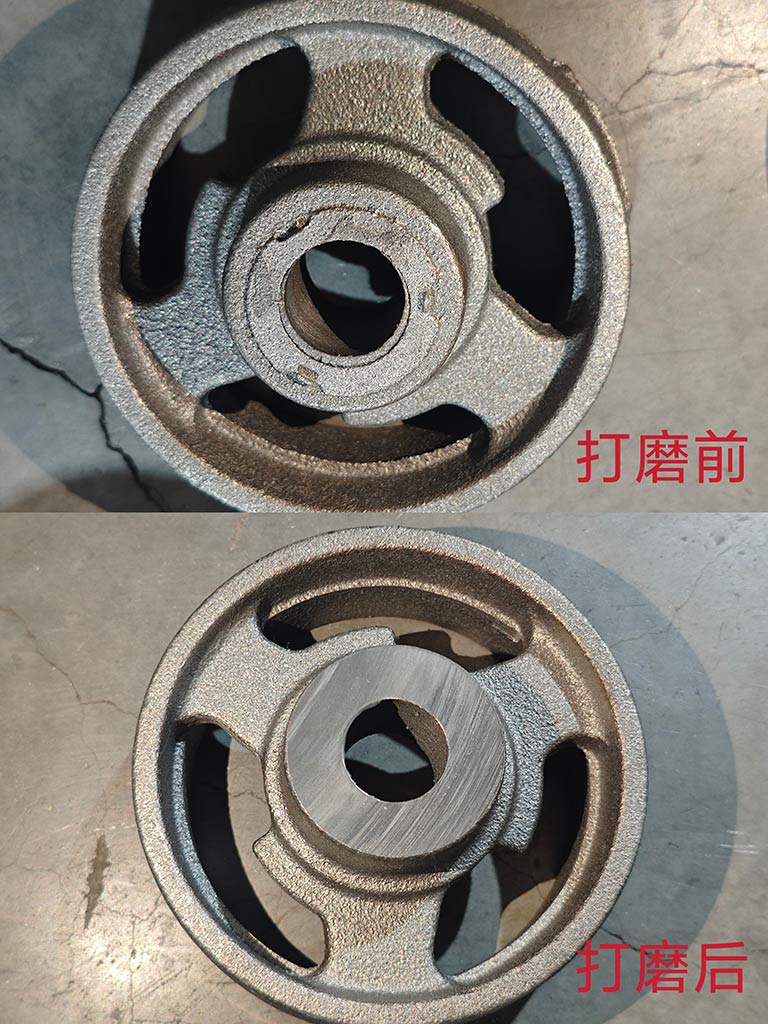

Precision and Consistency: Precision refers to the robot’s ability to consistently apply the correct amount of force and movement during grinding. Consistency refers to the robot's ability to replicate the same result across multiple parts, ensuring uniform quality.

Grinding Programs and Optimization Algorithms: Robots operate using pre-programmed paths and parameters. Optimization algorithms allow the robot to adapt its movements in real-time, adjusting to variations in the workpiece to ensure the best grinding result.

A solid understanding of these key terms is crucial for selecting the right robotic grinding solution. By understanding the technologies and their implications, foundries can make better decisions and achieve superior results in their operations.

Read More