May 09, 2024

Neview Automatic Empowers Chery's Cast Iron and Aluminum Foundries for Efficient Grinding, Setting New Quality Standards

In the automotive parts manufacturing sector, the grinding process is crucial, directly impacting product quality and performance. As a leading brand in the automotive industry, Chery holds exceptionally high standards for the grinding of its cast iron and aluminum alloy components. Neview Automatic Technology Co., Ltd. has now partnered with Chery's parts factory, introducing the DR-750B grinding robot to its cast iron foundry and equipping its aluminum foundry with the MR-750B grinding robot. This collaboration enables highly efficient grinding and the output of high-quality ground parts.

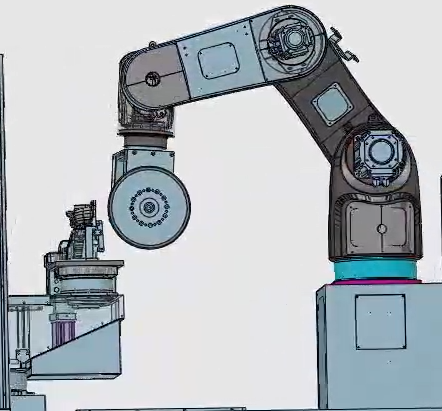

The Cast Iron Foundry's Efficient Grinding Solution: DR-750BThe DR-750B grinding robot, with its robust performance, perfectly meets the grinding demands of the cast iron foundry. Its flexible single-arm, dual-station configuration, combined with a workbench and robotic arm both capable of handling 400kg-level loads, allows it to effortlessly manage even large cast iron parts. The robot's Automatic Error Detection and Compensation System identifies variations in workpieces and automatically corrects the grinding path, precisely removing defects such as burrs and flash from cast iron surfaces. This ensures high grinding precision and delivers stable, reliable quality. Furthermore, the Intelligent Compensation and Flexible Conformity Technology addresses the tendency of cast iron parts to deform. By controlling the current loop, position loop, and torque loop, it achieves flexible grinding, guaranteeing that cast iron parts retain their original shape and performance during the process. This significantly enhances grinding efficiency and product quality in the cast iron foundry while reducing labor costs and workload.

The Aluminum Foundry's Precision Grinding Expert: MR-750BThe MR-750B grinding robot is specifically engineered for the intricate grinding tasks required in aluminum foundries. Aluminum castings are often complex in shape, thin-walled, and demand high precision. The MR-750B excels with its high-precision grinding capabilities, accurately processing aluminum castings. It features high-precision workpiece recognition, eliminating the need for complex teaching operations and greatly improving grinding efficiency and accuracy. Its grinding spindle offers high rotational speed and excellent stability, effectively removing burrs and oxide scale from aluminum surfaces. This results in smooth, flawless surfaces on aluminum castings, enhancing both their aesthetic quality and assembly performance. The MR-750B empowers Chery's aluminum foundry to produce components that meet high-end quality requirements, strengthening its competitiveness in the automotive parts market.

Neview Automatic is steadfastly committed to providing premium automated grinding solutions for the foundry industry. We deeply understand that only high-quality ground parts can provide a solid foundation for automotive manufacturing. In the future, we will continue to collaborate with Chery and other valued customers, relentlessly innovating and optimizing grinding technologies to contribute to the high-quality development of the automotive parts manufacturing industry.

Read More