Dec 01, 2025

Human-Robot Collaboration: The Most Practical Path for Automated Grinding Today

Many customers ask, “Can we achieve fully unmanned grinding?”

The reality is: full automation isn’t feasible yet. The most effective approach today is human-robot collaboration.

1.Why Is Full Automation Difficult?

Castings vary in deformation, batch differences, and irregular flash shapes. Robots excel at repetition, not judgment.

2.Human-Robot Collaboration Is More Efficient

The optimal workflow: manual loading/unloading, NEVIEW robots handling the main grinding paths, and humans handling the few ultra-complex areas.

3.Robots Handle the Standardized 80%

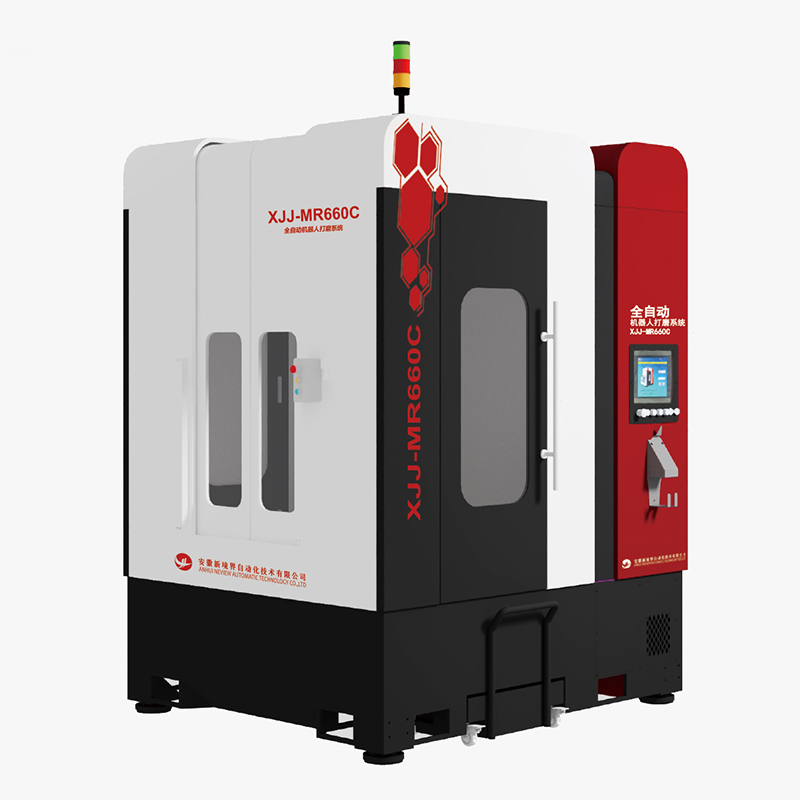

NEVIEW’s high-rigidity robotic arm and automatic path correction cover most standardized zones effectively.

4.Safety Benefits Are Underrated

Dust, noise, and vibration can harm workers. Robots isolate these hazards inside a fully enclosed safety cell.

5.More Predictable ROI

With faster deployment and lower risk, this model offers predictable ROI and is widely accepted in global factories.

Real automation isn’t about replacing people — it’s about letting humans and robots each do what they do best.

NEVIEW’s automation solutions are helping foundries worldwide achieve more stable and modern production.

Read More