Aug 06, 2025

With the continuous promotion of the "Made in China 2025" strategy, traditional casting enterprises are increasingly introducing automated grinding solutions in the process of transitioning to intelligent manufacturing. Among them, industrial grinding robots, as an important technology to replace manual grinding, are becoming a key equipment to improve the quality and production efficiency of casting processing.

1、 Pain point of manual grinding: restricting the efficiency improvement of casting production line

• High labor intensity: High dust and high noise environments have a significant impact on workers' health and pose a high risk of occupational diseases;

• Poor efficiency and stability: Due to the influence of workers' technical proficiency, the grinding quality fluctuates greatly;

High labor costs: With the increasing difficulty and high cost of employment, the operational burden on enterprises has increased;

There are many safety hazards: frequent problems such as grinding wheel splashing and workpiece cracking, which can easily lead to work-related accidents.

2、 Industrial grinding robot: reshaping the post-treatment process of casting

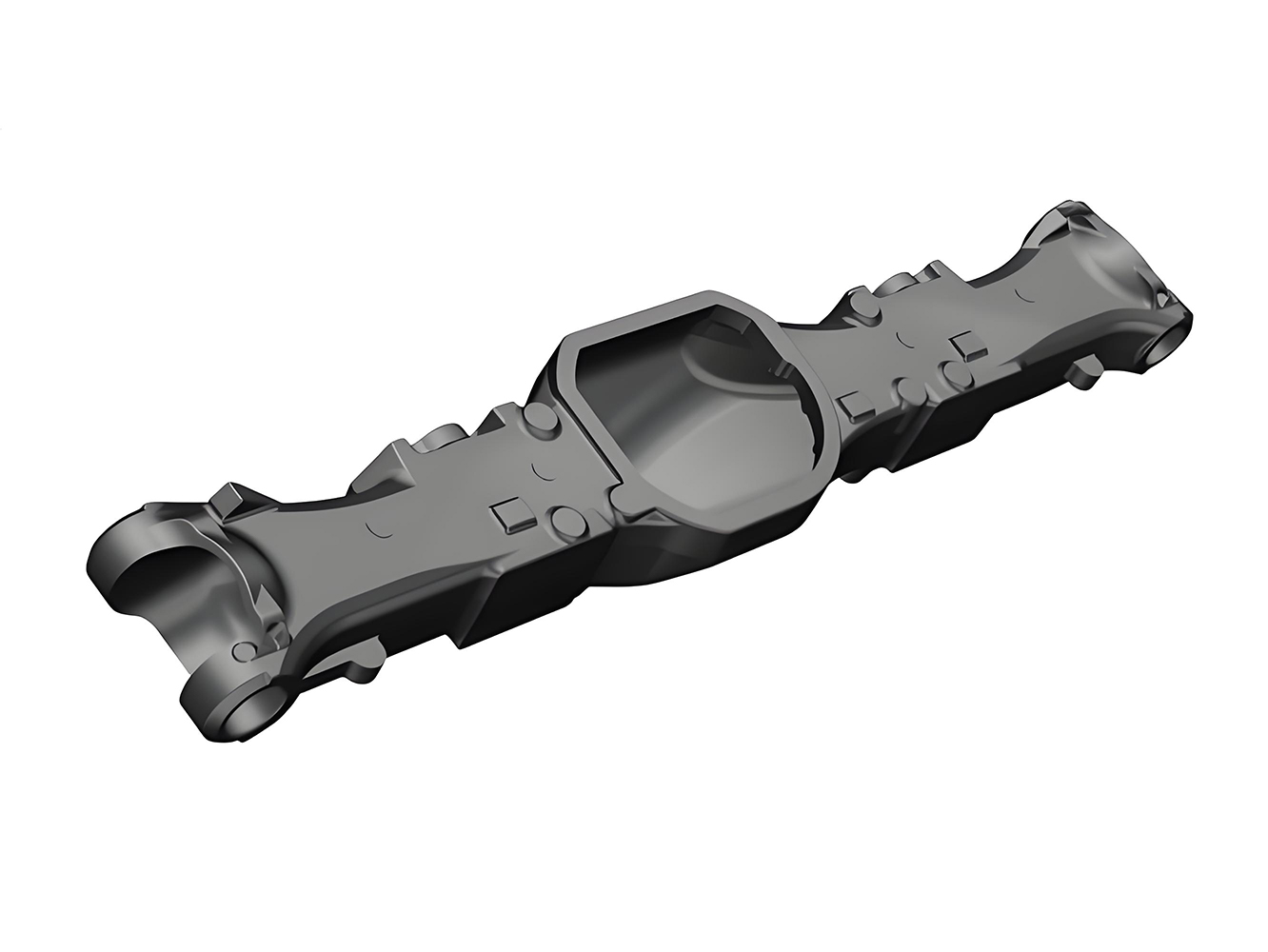

As a new generation of intelligent manufacturing equipment, the Neview Grinding Robot integrates multiple technologies such as force controlled grinding, laser detection, and flexible clamping to achieve precise and stable grinding of various complex workpieces such as cast iron, cast steel, and aluminum alloy. The main advantages include:

Intelligent deburring and corner processing to adapt to shape and position errors such as wrong box and wrong mold;

Operating 24/7, significantly reducing downtime;

One machine with multiple workstations design, suitable for batch and multi variety production needs;

Sealed and dust collection structure effectively reduces dust emissions and optimizes workshop environment

3、 Widely applicable scenarios: helping foundry enterprises reduce costs and increase efficiency

At present, industrial grinding robots have been widely used in various casting fields such as automotive parts, engineering machinery, rail transportation, pumps and valves. Many customer feedback indicates that the introduction of new realm grinding robots has increased production line efficiency by an average of over 30%, significantly improved grinding consistency, and optimized personnel configuration by over 50%, providing a solid foundation for enterprises to build long-term core competitiveness.

Read More