Oct 09, 2025

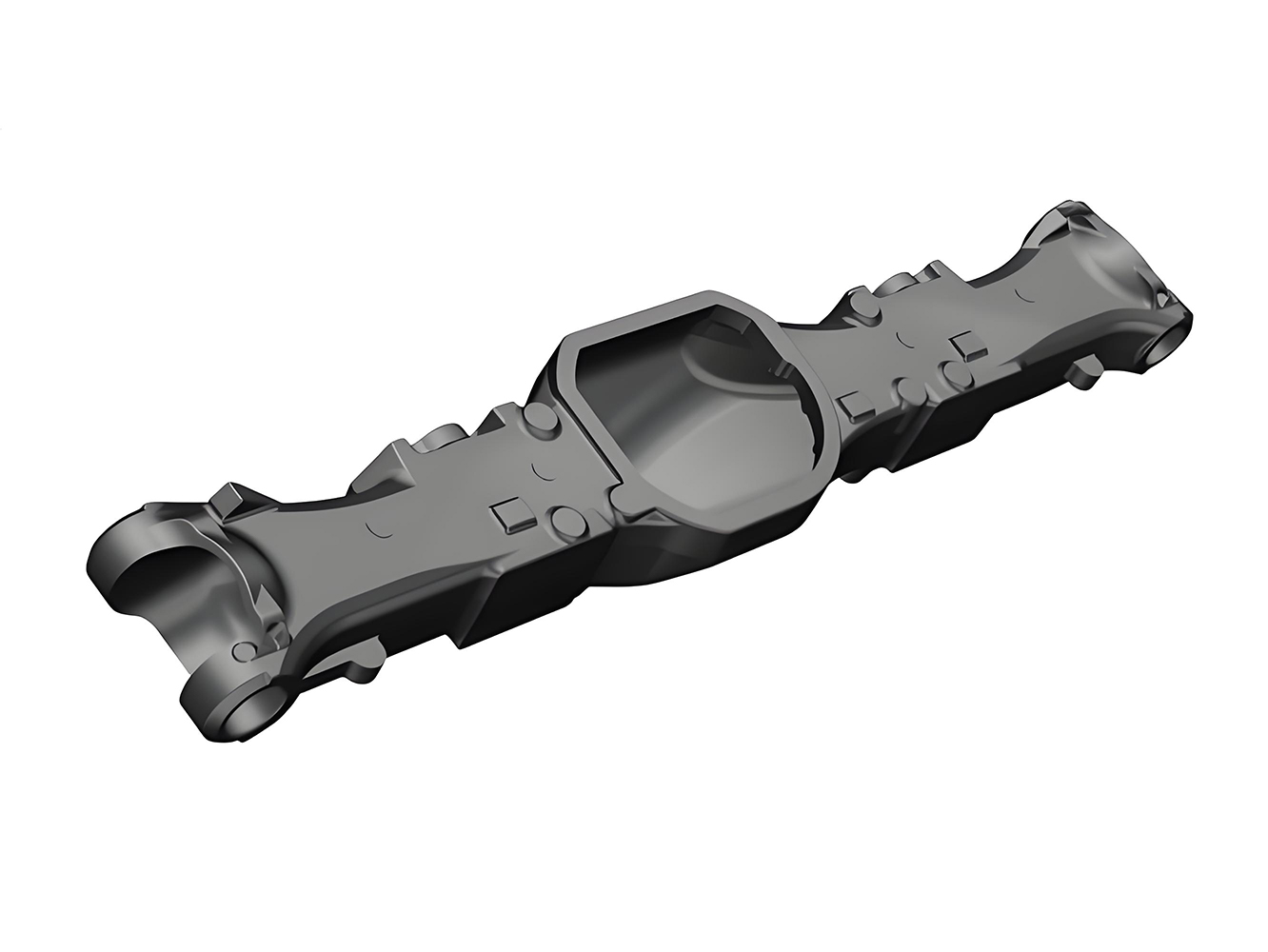

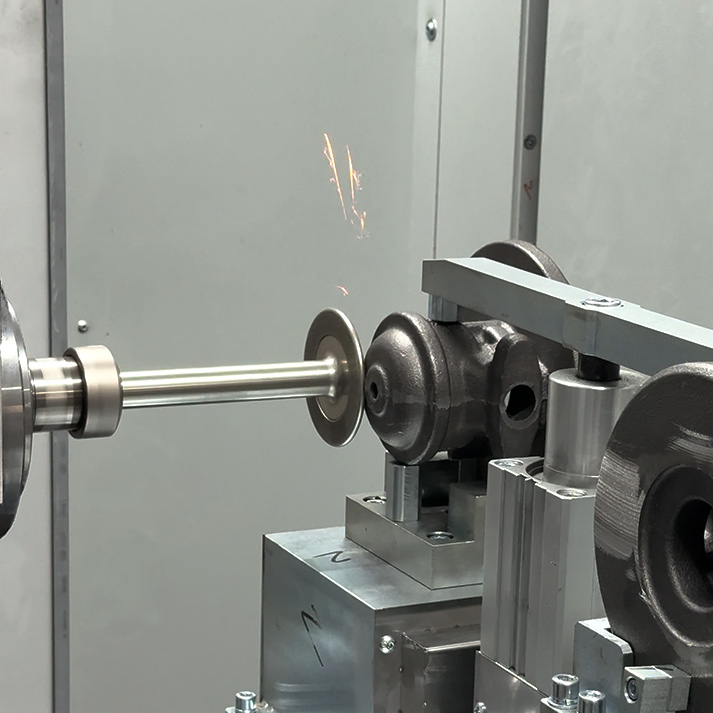

Manual vs Robotic Grinding — Which Is Better for Foundries?

Introduction

Is manual grinding or robotic grinding better for today’s foundries? Let’s compare them across efficiency, quality, safety, and cost.

Comparison Table

Dimension

Manual Grinding

NEVIEW GRINDING ROBOT

Efficiency

Prone to fatigue, limited output

Continuous operation, doubled efficiency

Quality

Depends on worker skill, inconsistent

Stable, precise, repeatable results

Safety

Dust and noise hazards

Enclosed operation, safer environment

Cost

Rising labor expenses

High ROI with long-term use

Conclusion

For modern foundries, automation is the inevitable trend. With stable and efficient performance, NEVIEW GRINDING ROBOT is replacing manual grinding step by step.

Read More