Lightweight Revolution Breakthrough in Aluminum Grinding: Neview Automatic’s Aluminum Series Empowers New Energy Vehicle Parts Manufacturer to Achieve Efficiency Leap

Amid the explosive growth of the new energy vehicle industry, the large-scale application of aluminum alloy components is driving innovation in post-casting processing. Neview Automatic, leveraging deep technical expertise in aluminum grinding, has delivered customized intelligent solutions to leading enterprises. The following case study examines how Neview Automatic’s aluminum series products overcame grinding challenges tied to aluminum material properties through a project for a new energy vehicle battery casing manufacturer (hereafter "the Customer").

As a TOP 3 domestic supplier of new energy battery casings, the Customer produces over 800,000 aluminum alloy battery trays and casings annually. Their original production line used traditional robotic grinding, exposing three bottlenecks directly linked to material properties:

Material Property Challenges: Aluminum alloy’s low hardness and high plasticity caused edge deformation under rigid grinding, resulting in 12% dimensional deviation and 18% burr retention.

Efficiency Ceiling: Daily output per station was limited to 1,200 pieces. Frequent model changes (requiring 4-hour shutdowns) severely disrupted capacity amid rapid vehicle iterations.

Environmental Compliance Pressure: Open grinding generated aluminum dust at 2.5× regulatory limits, while dry grinding caused internal chip accumulation, leading to 15% annual equipment failure rate.

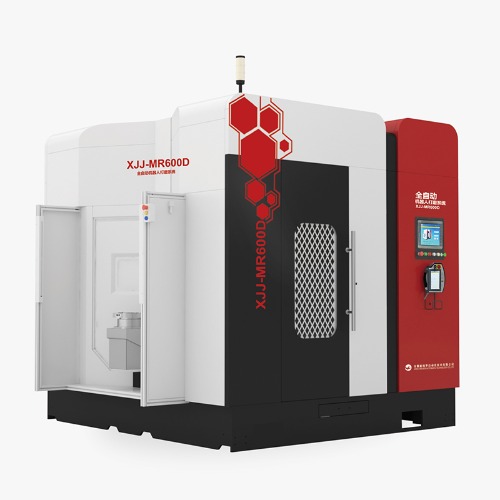

After 6 months of technical evaluation, the Customer selected Neview Automatic’s MR-600D dual-arm, triple-station equipment. Its 14-axis coordinated structure and ±0.02mm repeat positioning accuracy became the key to flexible aluminum grinding.

Neview Automatic’s solution centered on the MR-600D, establishing a 3D technical framework of "Material Adaptation – Process Optimization – Intelligent Control":

(1) Six-Axis Coordination + Flexible Force Control

The 14-axis system employs triple closed-loop control (current/position/torque) to achieve adjustable grinding force (0.1–3N). For deformation-prone battery casing flanges, "constant-force contour grinding" limits edge distortion to <0.03mm, reducing scrap rate from 8% to 0.8%.

(2) AI Vision + Unordered Sorting for Smart Logistics

Integrated 3D vision detects incoming part orientation, while adaptive grippers enable unordered pickup—boosting loading efficiency by 40%. AI sorting cut model changeover from 4 hours to 25 minutes, ideal for high-mix, low-volume production.

(3) Fully Sealed + Pulse Dust Extraction

Double-layer sealed steel housing with integrated dust collection achieves 95% chip capture, reducing workshop dust to 5mg/m³ (complying with GBZ2.1-2019). Internal chip accumulation dropped 90%, slashing annual failure rates to <3%.

Capacity & Quality: Daily output per line surged to 3,600 pieces (+200%). Dimensional tolerance held within ±0.04mm, burr retention <0.3%, passing CATL’s IATF 16949 audit.

Cost Optimization: Labor costs fell 65%, with annual energy savings of ¥850,000. Changeover costs reduced 70%, enabling simultaneous production of 10+ vehicle models.

The Customer’s Technical Director stated:"*Neview Automatic’s flexible grinding technology completely resolved aluminum deformation issues. The triple-station turntable and dual-robot coordination slashed cycle time from 25s/piece to 12s/piece—perfectly matching mass production demands for battery casings.*"