The MR-950C, is a 8-axis linkage single-station grinding system specifically designed for small aluminum components for up to 150kg and diameter 950mm aluminum castings

Item No :

MR-950COrder(MOQ) :

1 SetPayment :

TT 50% depositProduct Origin :

ChinaShipping Port :

China sea portLead Time :

90 DaysWeight :

5 TMR-950C 8-Axis Linkage Robot Grinding CNC Machine for Aluminum Castings

Key Parameters

|

MR-950C |

||||

|

Max. Machining Size (mm) |

Max.Load-Bearing (kg) |

Arm Load (kg) |

Number of Machining Axes |

Repeated Positioning Accuracy(mm) |

|

L950*W800*L650 |

150 |

150 |

8 |

±0.02 |

|

Spindle Power (kw) |

Operating Power (kw) |

Total Power (kw) |

Equipment Size (mm) |

Equipment Weight (T) |

|

14.7/17.9 |

About 6 |

27/32 |

2400*2200*3100 |

5 |

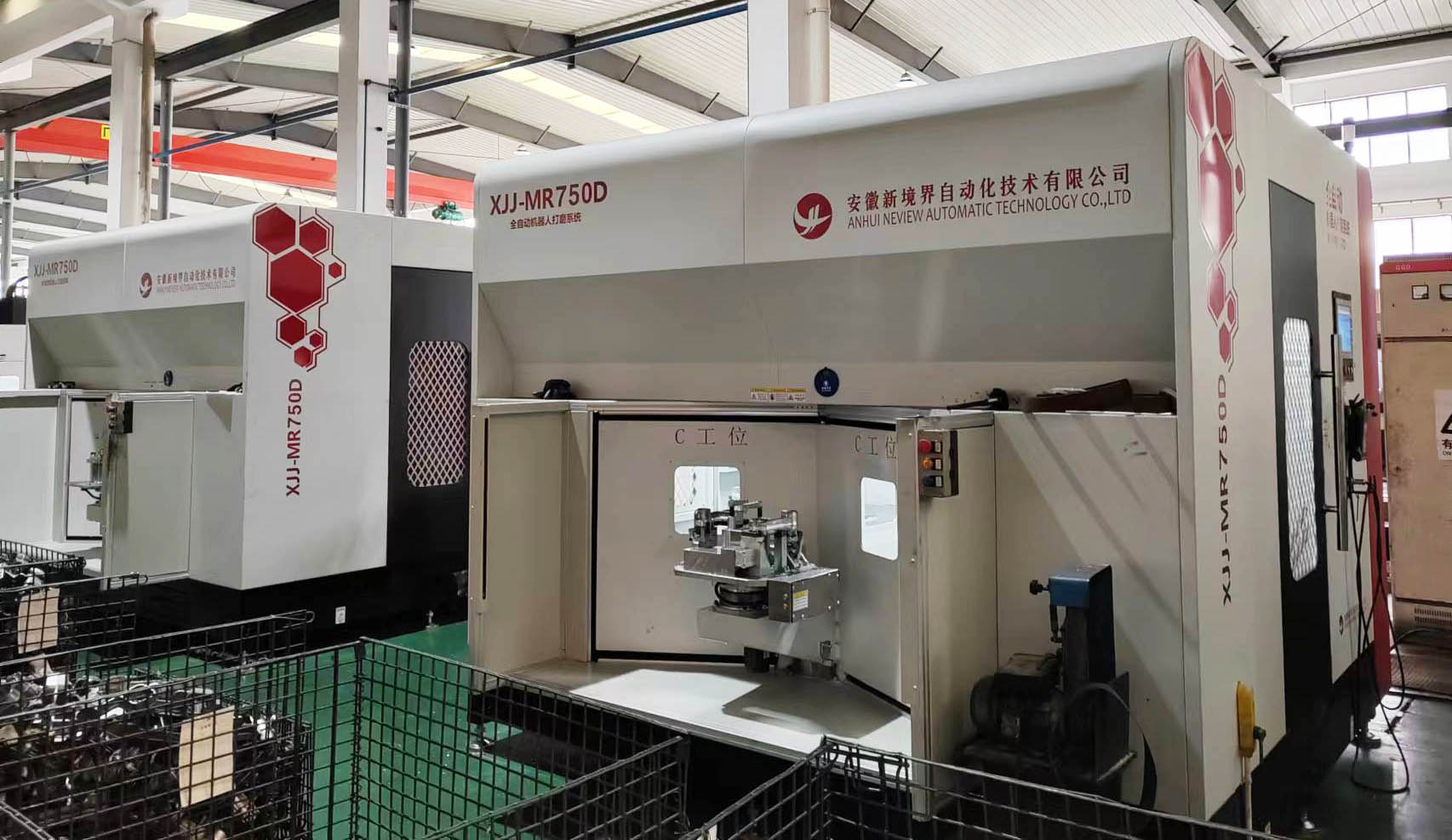

MR-950C Grinding Robot at Client's site

Make workshop clean and neat

Product Overview

The MR-950C, engineered by Neview Automatic, is an 8-axis linkage single-station grinding system specifically designed for small-to-medium aluminum components. Featuring dual-spindle configuration and 8-axis motion control, it delivers high-precision grinding with flexible production capabilities. Optimized for precision machining through its single-station design, it is ideal for post-processing tasks such as deburring and polishing of batch-produced aluminum parts—including automotive components and electronics heat sinks—particularly suited for high-mix, low-volume (HMLV) production scenarios.

Core Technical Advantages

Typical Application Scenarios

• Automotive: Batch grinding of aluminum parts (engine covers, new energy vehicle battery enclosures).

• Electronics: Deburring of large heat sinks and 5G equipment aluminum housings.

• Aerospace: Precision polishing of aluminum structural components and instrument housings.

Compatible Product Specifications

• Small-to-medium aluminum parts ≤150kg;

• Regular/irregular structural components within 950×1800×650mm (L×W×H);

• Workpieces requiring grinding precision (±0.02mm) and superior surface finish.

Innovation Highlights

Standard Configuration

• 8-axis robotic arm + single-station rotary table;

• Dual-spindle grinding system (14.7/19.7kW spindle motors);

• Automatic error detection & compensation system;

• Intelligent control system.