The MR-660C, is a 6-axis linkage single-station grinding system specifically designed for small aluminum components for up to 150kg and diameter 650mm aluminum castings

Item No :

MR-660COrder(MOQ) :

1 SetPayment :

TT 50% advance paymentProduct Origin :

ChinaShipping Port :

China sea portLead Time :

60 DaysWeight :

4 TMR-660C Six-Axis Linkage Robot Grinding CNC Machine for Aluminum Castings

Product Overview

The MR-660C, engineered by Neview , is a 6-axis linkage single-station grinding system specifically designed for small aluminum components. Featuring multi-spindle configuration and 6-axis motion control, it delivers high-precision grinding with flexible production capabilities. Optimized for precision machining through its single-station design, it is ideal for post-processing tasks such as deburring and polishing of batch-produced small aluminum parts—including automotive components and electronics heat sinks—particularly suited for high-mix, low-volume (HMLV) production scenarios.

MR-660C Grinding Robot at Client's site

Make workshop clean and neat

Key Parameters

|

MR-660C |

||||

|

Max. Machining Size (mm) |

Max.Load-Bearing (kg) |

Number of Machining Axes (kg) |

Number of Machining Axes |

Repeated Positioning Accuracy(mm) |

|

L650*W560*L450 |

150 |

4/6 |

8 |

±0.02 |

|

Spindle Power (kw) |

Operating Power (kw) |

Total Power (kw) |

Equipment Size (mm) |

Equipment Weight (T) |

|

14.7/17.9 |

About 6 |

26/31 |

2100*1900*2700 |

4 |

Core Technical Advantages

6-Axis Flexible Machining Capability

• 6-axis linkage supports complex spatial trajectory machining, enabling multi-angle curved surface grinding to cover >80% of small aluminum part types.

• Compared to traditional 5-axis systems, the MR-660C achieves continuous curve machining, especially effective for complex structures like aluminum housings and irregular parts.

Multi-Spindle Hybrid Processing System

• Standard 4-6 spindle grinding system accommodates diverse tools (e.g., grinding wheels, flap discs, wafer discs), completing roughing and finishing in one setup.

• Spindle power (14.7-17.9kW) enables efficient aluminum material removal, increasing grinding efficiency by 30% vs. conventional equipment.

Intelligent Error Compensation Technology

• Integrated displacement sensors automatically detect casting variations and adjust grinding paths to accommodate aluminum’s deformation tendencies.

• Flexible contour grinding via current-loop and torque-loop control prevents under/over-grinding, ensuring precision for thin-walled parts.

Single-Station Precision Machining

• Dedicated high-accuracy design achieves repeat positioning precision of ±0.02mm, ideal for aluminum polishing requiring superior surface finish.

• Quick-change fixtures enable ≤15-minute model changeovers, adapting seamlessly to HMLV production.

Typical Application Scenarios

• Automotive: Batch grinding of small aluminum parts (engine covers, brake calipers).

• Electronics: Deburring of aluminum components (heat sinks, enclosures).

• Medical Devices: Precision polishing of surgical instruments and equipment housings.

Compatible Product Specifications

• Small aluminum parts ≤150kg;

• Regular/irregular structural components within L650×W560×H450mm dimensions;

• Workpieces requiring high grinding precision (±0.02mm) and superior surface finish.

Innovation Highlights

6-Axis Flexible Grinding Technology

• Proprietary 6-axis control algorithm enables grinding at arbitrary 3D angles, increasing flexibility by 50% vs. traditional systems.

• CAD model direct-import programming slashes new product commissioning time by 50%.

Aluminum-Optimized Grinding Process

• Parameters and tooling (flap/wafer discs) tailored to aluminum properties effectively prevent chip adhesion.

• Integrated coolant circulation system enhances surface quality and reduces tool wear.

Standard Configuration

• 6-axis robotic arm + single-station rotary table;

• Multi-spindle grinding system (14.7/17.9kW spindle motors);

• Automatic error detection & compensation system;

• Chinese intelligent control system.

Project achievement

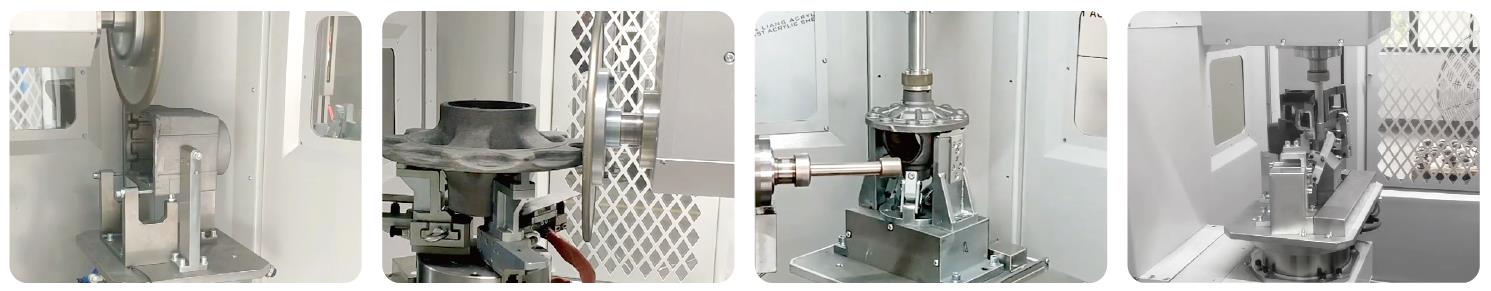

Fixture selection

|

|||

| Simple fixtures | Self-clamping fixtures | Pressing fixtures | Automatic avoidance fixture |

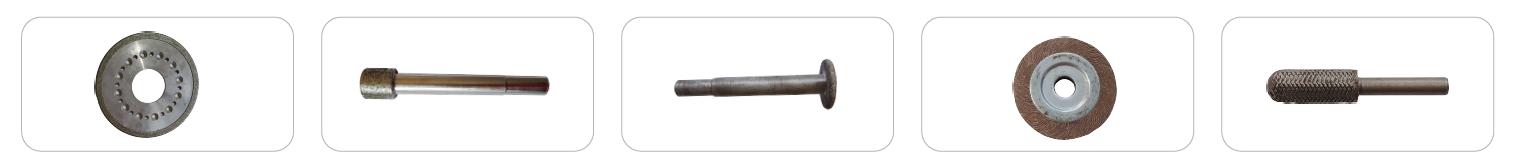

Grinding tool

|

|||||

| Grinding wheel | Grinding bit | Thin blade | Flap wheel | Rotary file | |

|

|||||

| Disc cutter | Milling cutter | Flap wheel | Abrasive band | Bristle brush | |

Application industry

Automobile, aviation, high-speed rail, 5G, new energy, military industry, power, engineering machinery, household appliances

About Neview

| Anhui Provincial Science and Technology Progress Award | |

| ISO 9001 Quality Management System Certificate | |

| ISO 45001 Safety Management System Certificate | |

| ISO 14001Environment Management System Certificate | |

| High tech Enterprise | |

| "Little Giant" Enterprise | |

| Digital Enterprise | |

| Industry university research cooperation base |