GR-750B Steel Casting Grinding System is for steel casetings up to 200kg and diameter 750mm with 5 axis single-arm, dual-workbench for casting foundry and plant

Item No :

GR-750BOrder(MOQ) :

1 SetPayment :

TT 50% advance payment.Product Origin :

ChinaShipping Port :

China sea portLead Time :

90 DaysWeight :

4.5 TGR-750B Automatic CNC Fettling And Finishing Robot Machine for Foundry Casting

Key Parameters

|

GR-750B |

||||

|

Max. Machining Size (mm) |

Max.Load-Bearing (kg) |

Arm Load (kg) |

Machining Axles |

Repeatability (mm) |

|

φ750*H550 |

200 |

200 |

8 |

±0.02 |

|

Spindle Power (kw) |

Operating Power (kw) |

Total Power (kw) |

Equipment Size (mm) |

Equipment Weight (T) |

|

16.5 |

5.5 |

42 |

3200*2150*2650 |

4.5 |

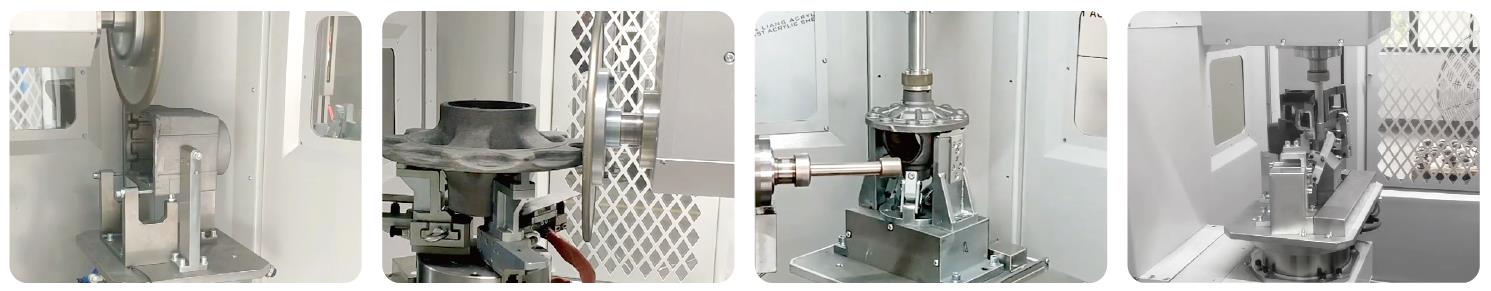

GR-750B is a 5 axis single robot arm, dual-workbench grinding system specifically developed for small-to-medium cast iron parts. Featuring 8-axis/7-linkage core technology and a dual-spindle configuration, it delivers both high-precision grinding and efficient production capabilities. Its rotary dual-workbench enables simultaneous loading/unloading and grinding operations, significantly boosting productivity. Ideal for post-processing tasks like deburring and polishing of batch-produced iron components such as automotive parts and engineering machinery accessories.

Product advantages

|

|

|

|

|

|

|

Ultimate Rigidity & High Payload |

Intelligent Compensation & Flexible Grinding System |

High Flexibility |

Safety, Eco-Friendly & Easy Maintenance |

Dual-workbench High-Efficiency Operation |

|

Worktable and robotic arm synchronously handle payloads up to 200kg. Reinforced reducers and arm structures achieve combined rigidity exceeding 400kg, ensuring stable processing of large sprue /gate remnants. The appliedforce is greater than 165 kg The structure design is equivalent to the rigidity of KUKA 400kg load. |

Standard displacement sensors automatically identify workpiece variations and adjust grinding paths to accommodate significant casting tolerances. For easily deformable workpieces, triple closed-loop control (current, position, torque) enables compliant grinding with parametrically adjustable contact force. |

The workpiece rotation axis can rotate freely 360 degrees; Customize fixtures to coordinate and grind operations; The combination of 5-axis robotic arm and 2-axis fixture rotation enables a grinding coverage rate of over 90%,Higher coverage than other structures type. |

Double-layer steel guards with automatic electrical door locks and loading-area light curtains meet industrial safety standards. Sealed structure supports centralized dust extraction. Neat internal layout simplifies cleaning, complying with workshop 5S requirements. |

Rotary dual-workbench allows simultaneous loading/unloading and grinding. Integrated with automatic workbench -switching technology,productivity increases by >30%. Dual-spindle grinding system concurrently performs roughing and finishing operations, shortening single-process cycles. |

Technical Comparison

|

|

Neview (Tool-type Grinding Machine) |

Workpiece-type Grinding Machine |

Belt Grinding Machine |

Robotic Grinding Workstation |

|

Tool |

Move |

Unmoved |

Unmoved |

Unmoved |

|

Workpiece |

Move & unmoved |

Move |

Move |

Unmoved |

|

Grinding Coverage |

High |

Medium |

Medium |

Low |

|

Workpiece available |

Various |

Small Workpiece |

Small Workpiece |

Various |

|

Grinding effect |

Heavy grinding |

Surface grinding |

Surface grinding |

Surface grinding |

|

Grinding accuracy |

High |

Low |

Low |

Low |

|

Environment |

Fully enclosed |

Enclosed |

Enclosed |

Open environment |

|

Safety |

High, The hollow interior design enhances the overall aesthetics of the device. |

High |

High |

Low |

|

Work efficiency |

High,Double or triple workbench, working with loading and unloading at the same time |

Low |

Low |

Low |

Client Pain Points

|

Client Pain Points |

Neview |

Common equipment |

|

Replace labor |

ü |

ü |

|

Improve environment |

ü |

ü |

|

Good grinding effect |

ü |

û |

|

Full work-piece coverage |

ü |

û |

|

Various work-piece |

ü |

û |

|

Easy programming and operation |

ü |

û |

|

Easy maintenance |

ü |

û |

|

Long service life |

ü |

û |

|

High-quality after-sales warranty |

ü |

û |

|

Support future equipment expansion compatibility |

ü |

û |

|

Wide range project application |

ü |

û |

|

Cheap price |

û |

ü |

Project achievement

Fixture selection

|

|||

| Simple fixtures | Self-clamping fixtures | Pressing fixtures | Automatic avoidance fixture |

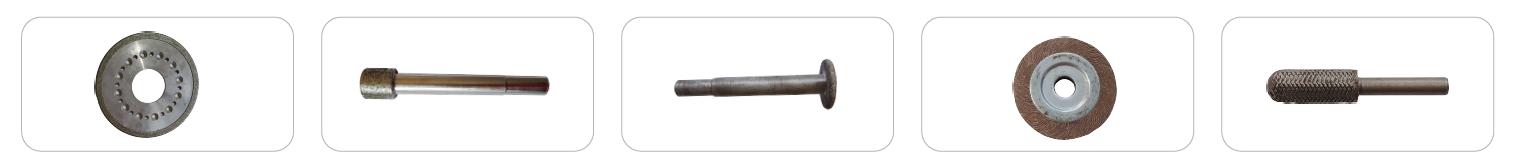

Grinding tool

|

|||||

| Grinding wheel | Grinding bit | Thin blade | Flap wheel | Rotary file | |

|

|||||

| Disc cutter | Milling cutter | Flap wheel | Abrasive band | Bristle brush | |

Application industry

Automobile, aviation, high-speed rail, 5G, new energy, military industry, power, engineering machinery, household appliances

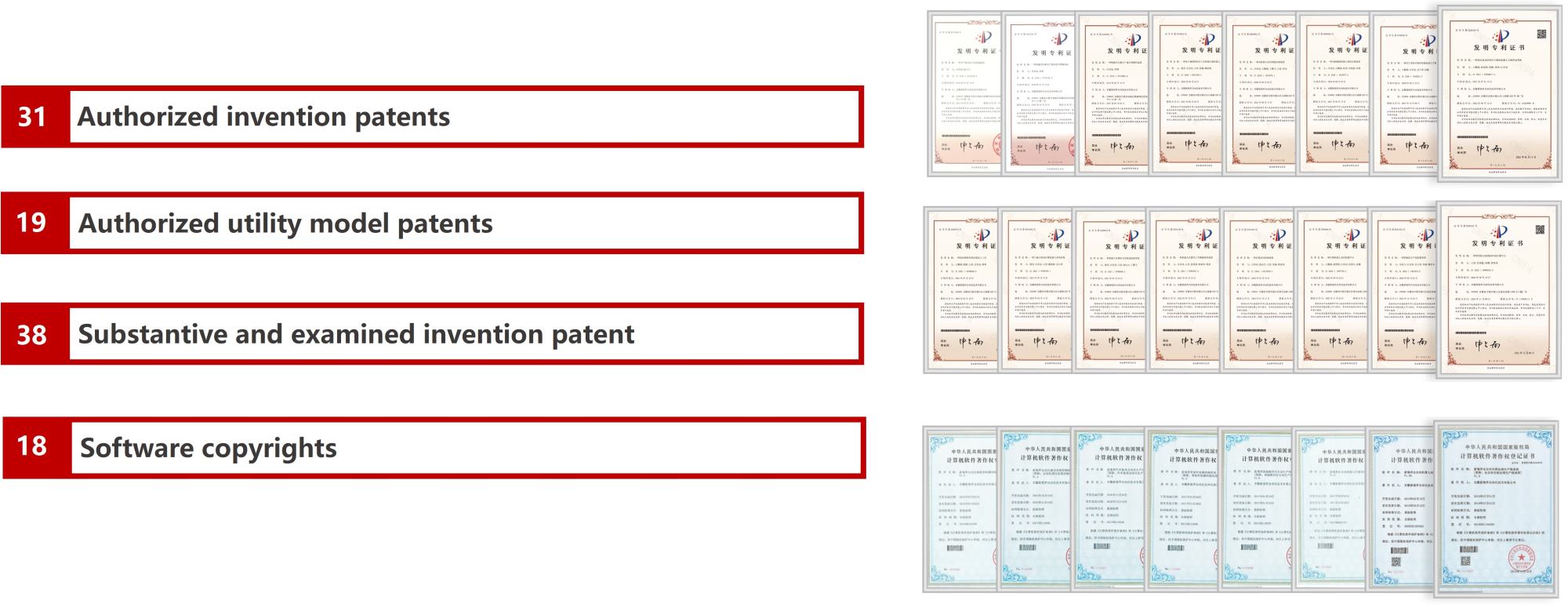

About Neview

| Anhui Provincial Science and Technology Progress Award | |

| ISO 9001 Quality Management System Certificate | |

| ISO 45001 Safety Management System Certificate | |

| ISO 14001Environment Management System Certificate | |

| High tech Enterprise | |

| "Little Giant" Enterprise | |

| Digital Enterprise | |

| Industry university research cooperation base |