Automatic cast grinding and cutting robot machine for the fettling and finishing of iron castings up to 200kg and diameter 550mm with 5 axis single-arm, dual-workbench for foundry.

Item No :

DR-550BOrder(MOQ) :

1 SetPayment :

TT 50% in advanceProduct Origin :

ChinaShipping Port :

China sea portLead Time :

60 daysWeight :

3.8 TProduct Overview

The DR-550B cast grinding robot machine, developed by Anhui Neview Automatic Technology Co., Ltd. is a single-arm, double-station robotic system specifically engineered for grinding small cast iron parts. Utilizing 8-axis linkage technology and a dual-spindle configuration, it achieves a balance of high-precision grinding and efficient production. The double-station rotary table design enables simultaneous loading/unloading and grinding operations, significantly reducing cycle time. It is ideal for post-processing tasks such as deburring and fettling of batch-produced small iron components like automotive parts and mechanical components.

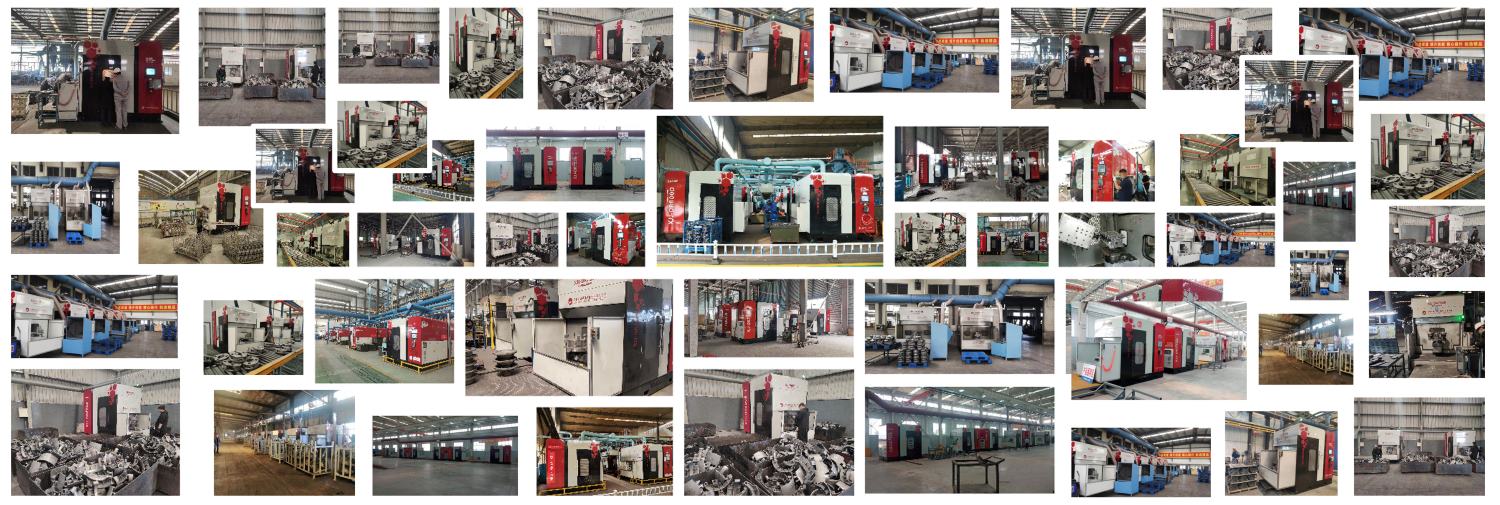

DR-550 Grinding Robot at Client's site

Key Parameters

|

DR-550B |

||||

|

Max. Machining Size (mm) |

Max.Load-Bearing (kg) |

Arm Load (kg) |

Machining Axles |

Repeatability (mm) |

|

φ550*H350 |

200 |

100 |

8 |

±0.02 |

|

Spindle Power (kw) |

Operating Power (kw) |

Total Power (kw) |

Equipment Size (mm) |

Equipment Weight (T) |

|

13 |

3.8 |

28 |

3010*1950*2600 |

3.8 |

Core Advantages

1. Ultimate Rigidity & High Payload Design

Worktable and robotic arm synchronously handle payloads up to 200kg. Through reinforced reducer and arm structure, the combined rigidity exceeds 400kg. Ensures stable performance for demanding tasks like cutting and grinding large sprue/gate remnants, with tested force output exceeding 165kg.

2. Intelligent Compensation & Flexible Grinding Technology

Standard displacement sensor detection system automatically identifies workpiece variations and adjusts grinding paths to accommodate significant casting tolerances.

For easily deform-able work pieces, achieves flexible contour-following grinding via current-loop, position-loop, and torque-loop control. Grinding force can be parametrically adjusted.

3. Efficient Double-Station Operation

Double-station rotary table design enables simultaneous loading/unloading and grinding. Combined with automatic station switching technology, productivity increases by over 30%, significantly reducing manual intervention frequency.

4. Safety, Environmental & Easy Maintenance

* Double-layer enclosed panels with automatic electrical door locks and loading-area light curtain protection comply with industrial safety standards.

* Integrated dust extraction ports on the protective structure. Neat internal layout facilitates easy cleaning, meeting workshop 5S management requirements.

Typical Application Scenarios

* Batch grinding of cast iron automotive parts (e.g., engine blocks, brake discs).

* Deburring and surface polishing of small engineering machinery components.

* Standardized post-processing of agricultural machinery parts.

Compatible Product Features

* Small-to-medium cast iron parts weighing ≤ 200kg.

* Structural parts (regular or complex) within dimensions of 550*H350mm.

* Workpieces requiring high grinding precision of ±0.02mm.

Innovation Highlights

1. 8-Axis Linkage for Flexible Processing

Compared to traditional 5-axis/4-linkage equipment, the DR-550B's 8-axis linkage structure enables continuous curved surface machining, covering over 80% of cast iron part types. Traditional 5-axis machines typically only handle around 30% of similar products.

2. AI-Assisted Intelligent Production

* Integrated AI vision recognition system supports high-precision workpiece positioning, reducing fixture constraints and lowering fixture costs by over 30%.

* Chinese programming interface coupled with model import auto-programming function increases teaching efficiency by 50%.

Standard Configuration

* Dual-spindle grinding system (13kW spindle motors).

* Automatic workpiece detection and compensation system.

* Double-layer protective steel panels with integrated dust extraction system.

* Intelligent control system.

* Core components: 1-year warranty, lifetime maintenance service.

Technical Comparison

|

|

Neview (Tool-type Grinding Machine) |

Workpiece-type Grinding Machine |

Belt Grinding Machine |

Robotic Grinding Workstation |

|

Tool |

Move |

Unmoved |

Unmoved |

Unmoved |

|

Workpiece |

Move & unmoved |

Move |

Move |

Unmoved |

|

Grinding Coverage |

High |

Medium |

Medium |

Low |

|

Workpiece available |

Various |

Small Workpiece |

Small Workpiece |

Various |

|

Grinding effect |

Heavy grinding |

Surface grinding |

Surface grinding |

Surface grinding |

|

Grinding accuracy |

High |

Low |

Low |

Low |

|

Environment |

Fully enclosed |

Enclosed |

Enclosed |

Open environment |

|

Safety |

High, The hollow interior design enhances the overall aesthetics of the device. |

High |

High |

Low |

|

Work efficiency |

High,Double or triple workbench, working with loading and unloading at the same time |

Low |

Low |

Low |

Client Pain Points

|

Client Pain Points |

Neview |

Common equipment |

|

Replace labor |

ü |

ü |

|

Improve environment |

ü |

ü |

|

Good grinding effect |

ü |

û |

|

Full work-piece coverage |

ü |

û |

|

Various work-piece |

ü |

û |

|

Easy programming and operation |

ü |

û |

|

Easy maintenance |

ü |

û |

|

Long service life |

ü |

û |

|

High-quality after-sales warranty |

ü |

û |

|

Support future equipment expansion compatibility |

ü |

û |

|

Wide range project application |

ü |

û |

|

Cheap price |

û |

ü |

Project achievement

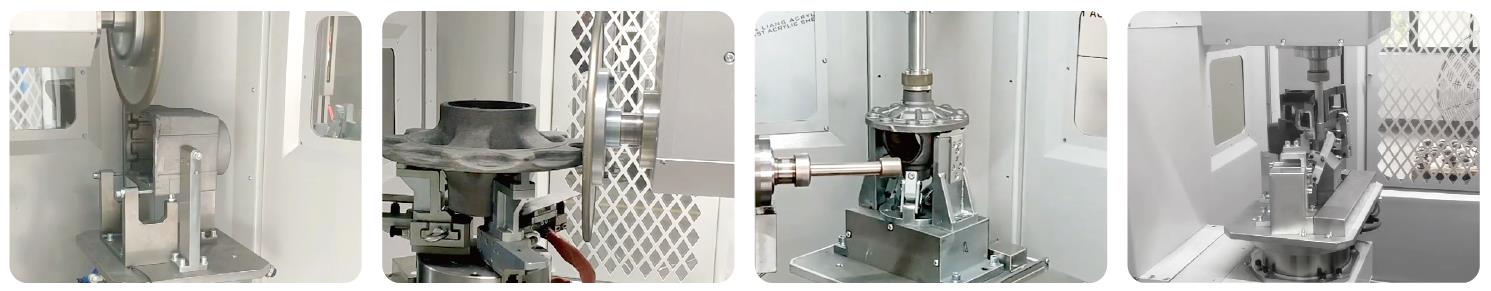

Fixture selection

|

|||

| Simple fixtures | Self-clamping fixtures | Pressing fixtures | Automatic avoidance fixture |

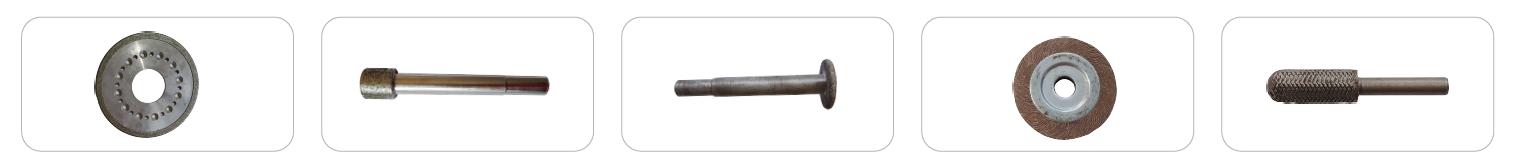

Grinding tool

|

|||||

| Grinding wheel | Grinding bit | Thin blade | Flap wheel | Rotary file | |

|

|||||

| Disc cutter | Milling cutter | Flap wheel | Abrasive band | Bristle brush | |

Application industry

Automobile, aviation, high-speed rail, 5G, new energy, military industry, power, engineering machinery, household appliances