Automatic CNC grinding and deburring robot machine for aluminum castings up to 150kg and diameter 150mm with 5 axis dual-arm, triple-workbench for casting foundry and plant

Item No :

MR-600DOrder(MOQ) :

1 SetPayment :

TT 50% advance paymentProduct Origin :

ChinaShipping Port :

China seaportLead Time :

90 DaysWeight :

6 TMR-600D Grinding Robot Machine for Aluminum Castings

Product Overview

The MR-600D, engineered by Neview , is a dual-arm, triple-station robotic grinding system designed for high-volume production of small-to-medium aluminum castings. Utilizing 14-axis linkage technology and a quad-spindle configuration, it achieves mass-production efficiency through dual-robot collaboration and a triple-station rotary table. This system delivers high-precision machining with flexible production capabilities, making it ideal for large-scale deburring and polishing of aluminum components such as automotive parts and electronics heat sinks.

MR-600D Grinding Robot at Client's site

Make workshop clean and neat

Key Parameters

|

DR-600D |

||||

|

Max. Machining Size (mm) |

Max.Load-Bearing (kg) |

Arm Load (kg) |

Number of Machining Axes |

Repeatability (mm) |

|

φ600*H350 |

150 |

150 |

14 |

±0.02 |

|

Spindle Power (kw) |

Operating Power (kw) |

Total Power (kw) |

Equipment Size (mm) |

Equipment Weight (T) |

|

22 |

7.0 |

55 |

2790*2980*2500 |

6 |

Core Technical Advantages

Typical Application Scenarios

• Automotive: Batch grinding of aluminum parts (engine covers, NEV battery enclosures).

• Electronics: Deburring of 5G equipment housings and large heat sinks.

• Aerospace: Precision polishing of aluminum structural components and instrument housings.

Compatible Product Specifications

• Small-to-medium aluminum parts ≤150kg;

• Regular/irregular structural components within Ø600×H350mm dimensions;

• High-volume production demand ≥50,000 units/year.

Innovation Highlights

Standard Configuration

• Dual robotic arms + triple-station rotary table;

• Quad-spindle grinding system (22kW spindle motors);

• Automatic error detection & compensation system;

• Intelligent control system with remote monitoring module.

Project achievement

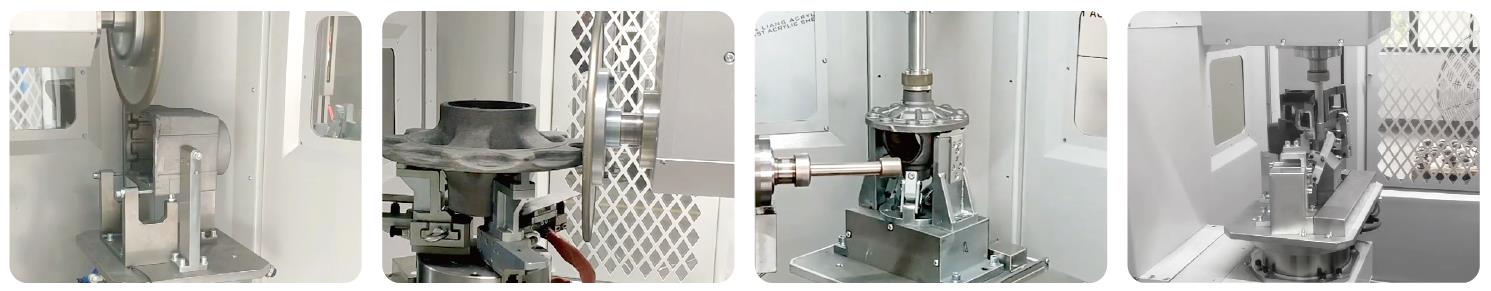

Fixture selection

|

|||

| Simple fixtures | Self-clamping fixtures | Pressing fixtures | Automatic avoidance fixture |

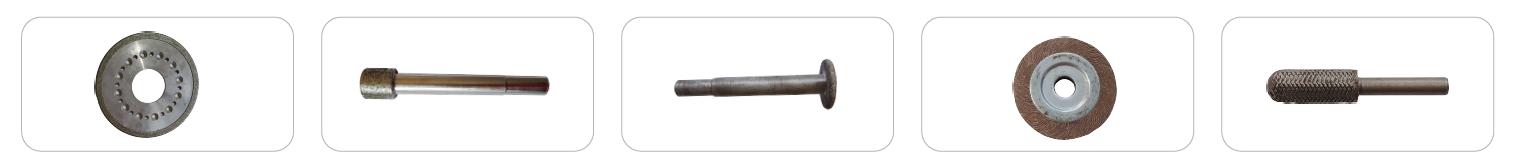

Grinding tool

|

|||||

| Grinding wheel | Grinding bit | Thin blade | Flap wheel | Rotary file | |

|

|||||

| Disc cutter | Milling cutter | Flap wheel | Abrasive band | Bristle brush | |

Application industry

Automobile, aviation, high-speed rail, 5G, new energy, military industry, power, engineering machinery, household appliances

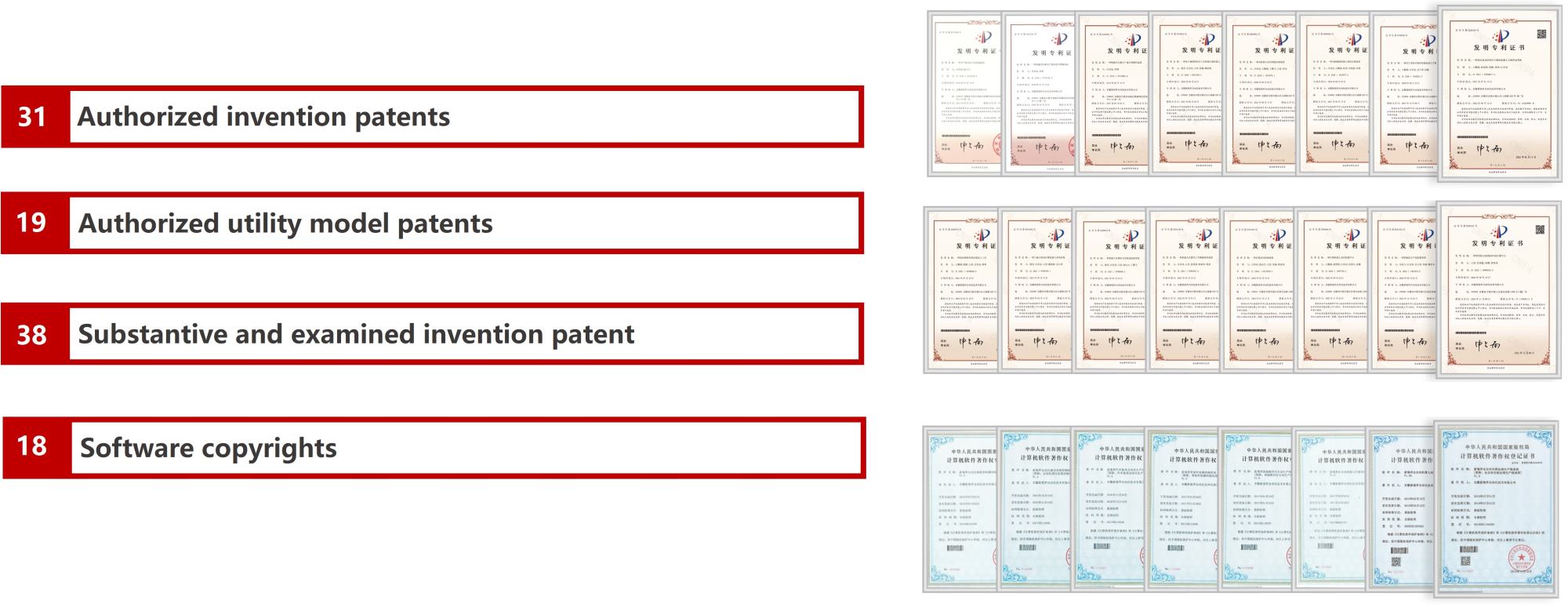

About Neview

| Anhui Provincial Science and Technology Progress Award | |

| ISO 9001 Quality Management System Certificate | |

| ISO 45001 Safety Management System Certificate | |

| ISO 14001Environment Management System Certificate | |

| High tech Enterprise | |

| "Little Giant" Enterprise | |

| Digital Enterprise | |

| Industry university research cooperation base |