Jul 26, 2025

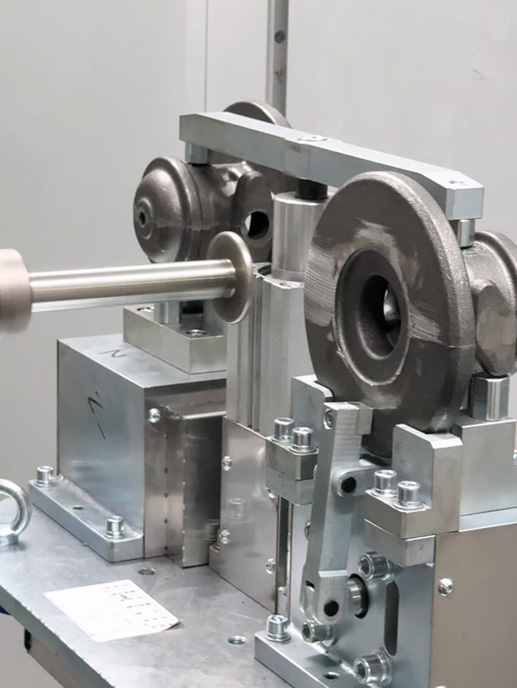

1.The fixtures are “replaceable and ready to use”, saying goodbye to polishing a single product The "workpiece positioning + arm grinding" mode is adopted, and the positioning reference of the fixture and the workpiece is completely unified. When changing products, you only need to fix the new fixture on the workbench and import the program through the control panel to realize the replacement and grinding of parts. A test of an agricultural machinery parts factory: changing from "gear cover" to "bearing seat" is 10 times faster than robot equipment.

2. Compatibility is "no blind spot", and complex parts can also be "ground in place"

The eight-axis seven-link structure gives the robot arm "anthropomorphic" flexibility: when facing complex parts with deep cavities, curved surfaces, and multiple holes (such as motor end covers and valve bodies), it can not only grind deep into the cavity, but also avoid protruding structures, and will not "fail to change the mold due to interference" like robot gripping equipment. An automobile parts factory verified that after changing the mold of its eight types of complex castings, the grinding completion rate remained above 95%, while the robot equipment could only achieve 60%.

Read More